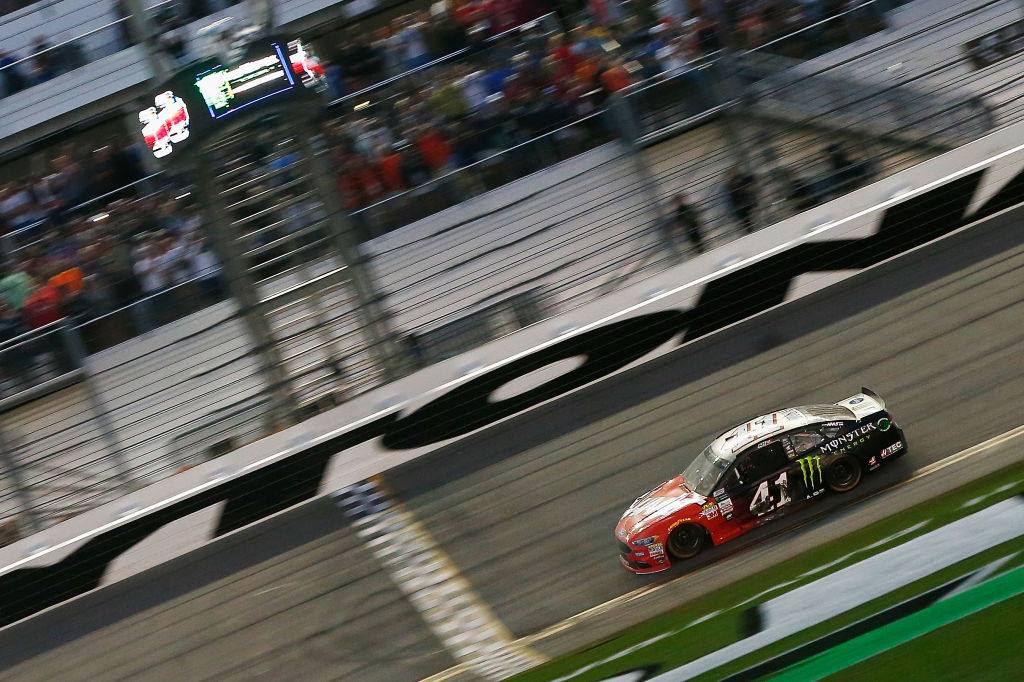

Photo: Stewart-Haas Racing

By Liz Allison, LizAllison.com

By Liz Allison, LizAllison.com

NASCAR racing has evolved many times since the birth of the sport in 1948. Driving your car straight from your garage to compete on the sandy beaches of Daytona Beach, Florida has become extinct as the 6th generation “stock cars” of today have hit their stride. “What wins on Sunday, sells on Monday” was the mantra for stock car enthusiasts during those times. Why? Because the same car that won the Southern 500 was available at the dealership down the street. And nothing sells like an affordable world-class racecar.

Although the days of the “stock” racecar are extinct, excitement exists in the now: faster car with tons of horsepower.

Among the biggest changes from the early days to 2017 are the engines built to compete in the Monster Energy NASCAR Cup Series. The engines of the 70’s would set you back a few hundred bucks, now the typical cost of a Cup-level engine is $100,000.

When Stewart-Haas Racing announced its plans to shift from Chevrolet to Ford, a switch that would take place at the end of the 2016 race season, it was about much more than just getting a new body on the car. Roush Yates Engines, the supplier of Ford engines in the Monster Energy NASCAR Cup Circuit, will now be in charge of the Stewart-Haas power.

Although the announcement came at the beginning of the 2016 season, the work at Roush Yates Engines began immediately. With the increased workload, twelve new employees were hired to help with the 60 engines to be built for Stewart-Haas. Add these to a combined total of 250 engines needed in 2017 for the entire Ford racing family, including SHR, Penske Racing, Roush Fenway Racing, Wood Brothers Racing, Richard Petty Motorsports, and Front Row Racing. The overall cost associated with switching SHR from Chevy to Ford sports a price tag of (roughly) $20,000,000.

It’s obvious that nothing is stock about stock cars in 2017. The idea of walking in your local Ford dealer and thinking you can walk out with your new Fusion ready to hit 200 mph like your favorite Ford driver on Sunday is just not going to happen. The most important factor in this is the Ford Performance FR9 engine is exclusive to NASCAR. The only actual “stock” component in the FR9 are the cylinder blocks and heads, manufactured by the same supplier as the production Fusion motor. The production Fusion engine costs (roughly) $7,500…. a bit less than the $100,000 of an FR9.

The original concept of the FR9 was the brainchild of second-generation engine builder Doug Yates and Roush Yates engineers, in collaboration with Ford Motor Company. The entire process was two years in the making from a clean sheet of scratch paper to the racetrack.

The work behind each engine is quite astonishing. It takes around 200 employees to make each FR9 engine. The process goes through six stages before an engine is race-ready. The stages include: Basic Concepts, Design, Manufacturing of Parts, Assembly of Engine, Validation (testing), and on-track performance. Once the parts are prepared, the engine specialists can build the engine in a day and a half.

With the start of the new NASCAR season, it may seem strange seeing SHR driver, Kurt Busch, Kevin Harvick, Danica Patrick, and new addition Clint Bowyer sporting the Blue Oval, but you can be rest assured they are bringing the best Ford Engines the manufacturer has to offer.

Engine Specs

Engine Name: Ford Performance FR9

Max RPM: 9500

Compression Ratio: 12.0:1

Horsepower: 800+

Torque: 525 ft-lb

358 cubic inches

Electronic Fuel Injection

Top Speed: 200+

Weight of Engine: 500 pounds

Liz Allison is an author, radio and television host who has been trackside for over twenty five years, first as the wife of the late, Davey Allison, and later a member of the sports media covering the NASCAR Sprint Cup, Nationwide and the Camping World Truck Series. Learn more about Liz at www.lizallison.com.